Last week I performed a mechanical bond stress test on an epoxy joint. The personal goal and reason I ran these tests are to determine if I must grind the entire surface of my boat deck down to raw fiberglass. A quick recap may be in order. We removed the teak decks (7000 or so screws, teak boards, the dense uneven bond of resin based product and seam caulk.) and repaired several places that had core rot. The rotted spots between the fiberglass now have hardwood mahogany rather than fiberglass to match the construction of the original work done by the Ta-Shing shipyard in Taiwan.

While I am confident in my repair and filling of all of the screw holes with a syringe, I want to be sure that after doing all of this work, I don’t have a water intrusion problem to the core again. That coupled with the added benefit of applying some additional strength to compensate for the removal of teak boards is why we will put a couple of layers of fiberglass down on the whole deck. Almost all of the feedback I have received indicates that the removal of teak will NOT reduce any strength in the boat, but I still think the additional layers certainly won’t hurt. If I was building a light weight racing boat, I might be worried about weight, but in the end, suspect that adding a couple of hundred pounds on a 58,000-pound boat just doesn’t matter.

The test last week showed impressive results, but now I want to see if I can do this same thing with Polyester resin which is about 35% of the cost of the epoxy resin.

This weeks test is to simulate the adding of 2 layers of woven roving on top of my existing deck with two different types of surface preparation. I used a section of the deck that I had cut out and removed when doing repairs (I knew they would come in handy for something).

The first part was ground all the way down to raw fiberglass, and the other section, much like in the last epoxy test was just sanded somewhat smooth with 36 grit but left some of the old gel coat and fairing material on the surface.

I picked up resin and catalyst from Ace Hardware because of it being fast and easy. After doing some research saw that the brand they carry is by American Plastics Incorporated who makes resin for many different companies and private labels it.

I picked up resin and catalyst from Ace Hardware because of it being fast and easy. After doing some research saw that the brand they carry is by American Plastics Incorporated who makes resin for many different companies and private labels it.

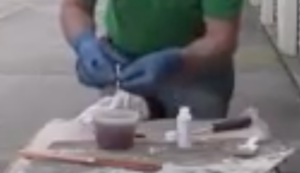

After cutting my woven roving pieces to fit my test section, I mixed up the solution of resin and catalyst. The manufacturer recommends a 1% catalyst mix so for 16oz of resin; I needed four ccs of the catalyst. I am using MEKP catalyst for this test and mixed it for just over 1 minute.

The supplies we use for this job are listed below if you find this a convenient way to shop for them. If you use these links, you get the same great Amazon pricing, but we get a small affiliate link credit. Thank you.

After applying a thin coat of the resin mix to the surface, I pressed the first layer of woven roving down against the tacky surface. I then poured a bit of the catalyzed resin onto the mat and used a 3″ chip brush to dab it down into the mat until it was translucent. It is at this moment in time I realize that I forgot my fin roller at the boat so used a small piece of PVC pipe to roll any air out from under it. The pipe was not optimal, but I think that since it is just to check the bond, it is good enough for my test.

I then added another layer of mat and repeated this process to the still wet surface below. I then added two layers of cross-strand mat as well.

I then added another layer of mat and repeated this process to the still wet surface below. I then added two layers of cross-strand mat as well.

I let this all sit and checked back on it about 26-28 hours later, and it was still wet. I attributed this to the fact that the weather cooled off and it dipped from the mid-70s when I first did this to mid 50’s overnight and into the second day.

Not having experience with this, I left it alone and let it sit another day. When I returned now a full 50 hours later, it was still not hardened at all. I was able to put on rubber gloves and just lift the mat off the surface by hand and fold it all up and throw it in a trash bag like a wet towel.

Based on the results, something went terribly wrong. It may have been temperature or the amount of catalyst. I had a hard time measuring the catalyst when I performed this test and opted to use a syringe that was designed for insulin since it had the CC measurements on the side of it. I removed the needle and just used the plastic syringe. Maybe that was the problem.

Either way, the test needs to be performed again. This particular one was a fail. I am reaching out to the manufacturer as well to see if I possibly did something wrong.

Either way, the test needs to be performed again. This particular one was a fail. I am reaching out to the manufacturer as well to see if I possibly did something wrong.