Last week we shared that we are going to be getting some fiberglass work done on the boat. We are going to be doing the decks and coach house. While the boat was in the yard, we moved onto our 43’ Gulfstar however that boat has somehow become smaller over time :).

Deb and I cruised on the Gulfstar for a few years along the gulf coast. There was plenty of room for us. Since we bought Dreamchaser, our 2 Grandkids and our Daughter have moved in with us. The 51’ Formosa was tight but manageable; the 43 was not. If we were on a passage or a 2-week trip, it would have been fine, but with Deb and I in the owner’s stateroom and McKinlee in the V-berth, it left Whitney and Chasity each to take one of the salon settees for sleeping. It was all the time when we were not sleeping that it was too tight.

So with that, we resurrected an old thought we have had for years about getting an RV. Deb and I looked around again at used RV’s. We were specifically looking for a Diesel Pusher which is like a bus with a diesel engine in the back. While we found many that were in great shape for a price we liked, we didn’t see any that were laid out in a way that would work for all of us and provide some privacy and separate areas for sleeping versus ‘living.’

We started looking for trailers that we could pull with our Tahoe to see if there were better options for all of us. We knew that the camper style of a “Bunkhouse” would allow for some additional bunk beds. We found one we liked and signed all the paperwork contingent on verifying that our vehicle could toe the trailer given its weight. Sadly, it was about 1000 pounds heavier than we could pull with our truck so we looked at other styles.

We found a Forest River Gray Wolf 30 foot Bunkhouse camper. It is correctly set up for the size of our family. It has a giant slide out to make the unit more abundant in the living area. Forward it has a queen centerline bed for Deb and me.

There is a large central area that has a safe, u-shaped dinette/settee and galley. There is also a rear room that has bunk beds on one side and a single bed on the other side which makes it perfect for all of us. I was surprised as it has a large Pantry, and the head with separate stand up shower has access from the central part of the camper, the owners stateroom or even from outside via a secondary door.

There is a large central area that has a safe, u-shaped dinette/settee and galley. There is also a rear room that has bunk beds on one side and a single bed on the other side which makes it perfect for all of us. I was surprised as it has a large Pantry, and the head with separate stand up shower has access from the central part of the camper, the owners stateroom or even from outside via a secondary door.To make additional space, there is also a secondary galley outside.

By having the camper, we were no longer struggling with the timeframe we had initially put on the yard which was to complete the work before Christmas. By adding the deck and coach house work, the timeframe is extending, and we have the buffer now with the camper. Lucky for us there are two state parks very close to us. One is about a half of mile from our marina, and the other is 10 miles or so the other way. State parks won’t allow you to stay more than 14 days in a row, so we are alternating back and forth between the 2 of them. Both are close enough that we can still just drive Chasity to the bus stop, so none of this work breaks up her routine for school.

Meanwhile, the work continues at the yard, and I am pleased with the progress. The mast has been primed and puts the first coat of paint. The color of the mast was not a great match to the current mast, and they let us know that the color was off and when they put the second coat on they will be placing the color that matches the primary mast as well. It is shocking to see the before and after on the mast for sure. From an old Spar that was laying in the yard for the last eight years to a newly cut and modified mast, specifically for our boat has been a cool transformation to see. By using an existing spar, we have saved thousands of dollars over buying a new one or having one made. There is more labor than you might expect if you ever embark into a job like this, but if you consider the fact that the supports for stays need to be modified, a new mast step needs to be fabricated, all new winch bases must be welded. All hardware must be drilled and tapped.

Meanwhile, the work continues at the yard, and I am pleased with the progress. The mast has been primed and puts the first coat of paint. The color of the mast was not a great match to the current mast, and they let us know that the color was off and when they put the second coat on they will be placing the color that matches the primary mast as well. It is shocking to see the before and after on the mast for sure. From an old Spar that was laying in the yard for the last eight years to a newly cut and modified mast, specifically for our boat has been a cool transformation to see. By using an existing spar, we have saved thousands of dollars over buying a new one or having one made. There is more labor than you might expect if you ever embark into a job like this, but if you consider the fact that the supports for stays need to be modified, a new mast step needs to be fabricated, all new winch bases must be welded. All hardware must be drilled and tapped.

There were structural supports to be added at places where things are through bolted like the hardware where the stays are attached.

Now that the boat has been splashed, it is getting ready for the deck work to begin. To be able to work for an extended period and contain the dust as well as protect from the weather they yard constructed a large tent structure over the boat. There were two options; the other was to pull the main and put it in the shop. However, they still would have had a similar problem in that sanding and grinding the deck would have scattered fiberglass dust all over the shop.

By doing this in the water with a tent on it, they were able to capture/contain the dust right on the deck and use a vacuum to obtain and collect it. It is incredible to see how much space there is inside the tent structure that they put up. It is made with a large 2” PVC mani structure and smaller 1 1/2” PVC arms that extend down to the toe rails. The use small 2/4’s with grooves cut in them to life one side of the other of the structure when they need to have a little extra space to work.

By doing this in the water with a tent on it, they were able to capture/contain the dust right on the deck and use a vacuum to obtain and collect it. It is incredible to see how much space there is inside the tent structure that they put up. It is made with a large 2” PVC mani structure and smaller 1 1/2” PVC arms that extend down to the toe rails. The use small 2/4’s with grooves cut in them to life one side of the other of the structure when they need to have a little extra space to work. They ground the deck with 24 grit to the bare glass. This was quite a job I am sure. I know I worked for two days straight at about 6 hours per day with my small grinder to get the surface just somewhat smooth after removing the teak. I was mainly sanding off the adhesive or epoxy that was used below the teak deck. It was noisy, messy and I am sure my marina neighbors hated it. When I would check on the boat while they were sanding this down, there would be piles of dust that they were sweeping up or vacuuming up.

They ground the deck with 24 grit to the bare glass. This was quite a job I am sure. I know I worked for two days straight at about 6 hours per day with my small grinder to get the surface just somewhat smooth after removing the teak. I was mainly sanding off the adhesive or epoxy that was used below the teak deck. It was noisy, messy and I am sure my marina neighbors hated it. When I would check on the boat while they were sanding this down, there would be piles of dust that they were sweeping up or vacuuming up. There was a small water channel that ran along the gunwales to scuppers midway down the deck. We talked about having the fiberglass go from just under the toe rail and down the gunwale and transition to the horizontal deck to keep it solid and sealed up. To minimize the labor we decided to fill in that water channel that ran along the gunwale and just glass over it. The yard cut foam strips to fill in the gap the then contoured the edge for the transition from the gunwale to the deck. This week they have started laying that glass on those gunwales and about 3-4 inches onto the deck. By doing this around the gunwales and the coach house, it will provide a surface to bond to when the entire deck is laid as well.

There was a small water channel that ran along the gunwales to scuppers midway down the deck. We talked about having the fiberglass go from just under the toe rail and down the gunwale and transition to the horizontal deck to keep it solid and sealed up. To minimize the labor we decided to fill in that water channel that ran along the gunwale and just glass over it. The yard cut foam strips to fill in the gap the then contoured the edge for the transition from the gunwale to the deck. This week they have started laying that glass on those gunwales and about 3-4 inches onto the deck. By doing this around the gunwales and the coach house, it will provide a surface to bond to when the entire deck is laid as well. They have not only ground down the deck, but also ground and sanded the wooden gunwales down to bare wood to provide a better surface for the glass to adhere to. In the Anchor well where you see a more substantial or higher section of the gunwale, this is obvious. They also sanded the anchor well down, and we will be re-shaping the bottom of this well to provide better water flow to the drains. This has been a problem on the boat previously, and I suspect was an area of leakage in the past.

They have not only ground down the deck, but also ground and sanded the wooden gunwales down to bare wood to provide a better surface for the glass to adhere to. In the Anchor well where you see a more substantial or higher section of the gunwale, this is obvious. They also sanded the anchor well down, and we will be re-shaping the bottom of this well to provide better water flow to the drains. This has been a problem on the boat previously, and I suspect was an area of leakage in the past. It was fascinating to see how they filled the gap between the coach house and the deck of the boat. Initially, when there were teak decks on the boat, there would have been a rounded coved out piece of teak in this space. When we bought DreamChaser, there was one on one side of the coach house, but the other side and front did not have it which also likely led to some of the leaking problems we experienced.

It was fascinating to see how they filled the gap between the coach house and the deck of the boat. Initially, when there were teak decks on the boat, there would have been a rounded coved out piece of teak in this space. When we bought DreamChaser, there was one on one side of the coach house, but the other side and front did not have it which also likely led to some of the leaking problems we experienced. The yard used an expanding 2 part foam, similar to the stuff you see at home improvement stores in a spray can fill the gap. When it was fully hardened, they would use a blade to trim it to the shape they wanted to achieve to blend the glass from the coach house to the deck. The strength comes from the Fiberglass, and the foam is just there to provide a surface to create the shape. In this second picture, you can see an example of where it has already been trimmed to create a smooth surface to lay the fiberglass matt across.

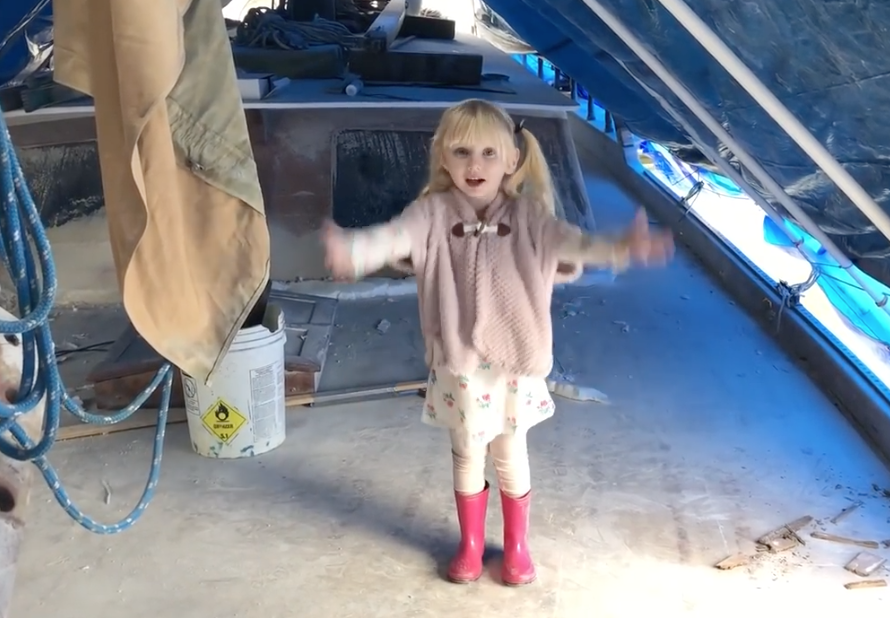

The yard used an expanding 2 part foam, similar to the stuff you see at home improvement stores in a spray can fill the gap. When it was fully hardened, they would use a blade to trim it to the shape they wanted to achieve to blend the glass from the coach house to the deck. The strength comes from the Fiberglass, and the foam is just there to provide a surface to create the shape. In this second picture, you can see an example of where it has already been trimmed to create a smooth surface to lay the fiberglass matt across. One on of my trips down to the boatyard, I took McKinlee (Swab) with me, and she was so jumping up and down telling me “I am so excited” and when I asked why she let me know it was because she was standing on this big new deck. I don’t think she realized it had only been sanded, but she did know it looked different for sure.

One on of my trips down to the boatyard, I took McKinlee (Swab) with me, and she was so jumping up and down telling me “I am so excited” and when I asked why she let me know it was because she was standing on this big new deck. I don’t think she realized it had only been sanded, but she did know it looked different for sure.I always like when she is excited and smiling. It warms my heart every time. She is a cutie pie, but then again I am biased 🙂

The video showing more detail of the information shared above can be found on our youtube channel. Please follow the channel by subscribing by clicking HERE. See the video below.

[embedyt] https://www.youtube.com/watch?v=CHGW7vhopQA[/embedyt]